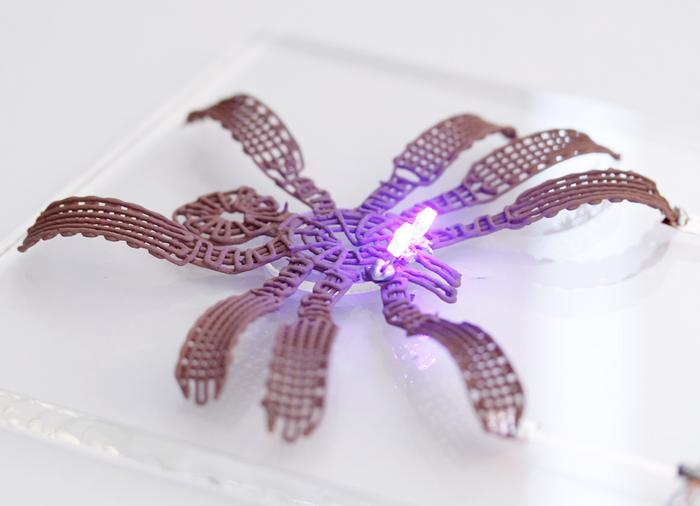

3D printing is getting fascinating day by day as well as have potential applications in various fields. Another important study has been done recently in the field of metal 3D printing. The printable metallic gel made up of suspension of copper particles connected by bridges of liquid eutectic gallium indium alloy (EGaIn) have extremely high conductivity as reported in the published paper of Cell. Ruizhe Xing and their co-workers have made a highly conductive spider by 3D printing. Also, they have added another dimension in 3D printing i.e., time and called it 4th dimension.

“3D printing has revolutionized manufacturing, but we’re not aware of previous technologies that allowed you to print 3D metal objects at room temperature in a single step,” says Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University. “This opens the door to manufacturing a wide range of electronic components and devices.”

How they made

The printing of the conductive spider is done by using the 3D ink of metallic suspension or metallic gel. For that, first the researchers prepared a suspension of copper microparticles in water to make the metallic gel. Then they inject a small quantity of liquid metal indium-gallium(Ga-In) alloy at room temperature. The resulting mixture is then mix together to make a gel kind of network. The gel consist copper particles suspended with liquid metal (EGaIn) in the aqueous solution. The Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University talked about how the consistency of metallic suspension is important in the printing process.

Maker’s says:

Dickey says. “This does two things. First, it means the network of particles connect to form electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.” The ink made of gel then printed using conventional 3D printing nozzle and retains its shape when printed. The “print” allowed to dry at room temperature which allow to solidifying the structure while retaining its shape. They suggest the room temperature drying to avoid any structural deformation. The time taken in solidifying the printed structure leads to add another dimension in the 3D printing and they come up with new term i.e., 4D printing.

The results

“Ultimately, this sort of four-dimensional printing – the traditional three dimensions, plus time – is one more tool that can be used to create structures with the desired dimensions,” Dickey says. “But what we find most exciting about this material is its conductivity. “Because the printed objects end up being as much as 97.5% metal, they are highly conductive. It’s obviously not as conductive as conventional copper wire, but it’s impossible to 3D print copper wire at room temperature. And what we’ve developed is far more conductive than anything else that can be printed. We’re pretty excited about the applications here. We’re open to working with industry partners to explore potential applications, and are always happy to talk with potential collaborators about future directions for research,” Dickey says.